|

SimulatorOur driver-in-loop simulator is mind-blowing. By simulating the track environment, we can support both current and future car development as well as driver training. It’s used regularly by our race drivers and test drivers as an invaluable preparation for track success. |

|

|

|

|

Race BaysThis is where the cars are prepared for their next race and where all the pieces of the puzzle fit together. Our highly skilled mechanics assemble all of the carefully engineered parts in a carefully orchestrated burst of activity. Returning from a race, the cars are stripped down, serviced, examined and tested to ensure reliability. |

|

|

|

|

Test and Development CentreWe have a state-of-the-art Test and Development Centre that measures the performance, compliance and endurance of the car. The facility houses cutting-edge technology and test rigs, operated by highly skilled technicians and engineers. This setup allows us to simulate track impacts so that we can analyse the loads acting on the car in dynamic conditions. |

|

|

|

|

Aerodynamics DepartmentAttention to detail is critical in our Aerodynamics Department. Using state-of-the-art Computational Fluid Dynamics tools, we can visualise how air will flow around the race car. From this understanding we can refine our designs before they are tested in the wind tunnel. This allows us to evaluate what impact they will have on our lap time. |

|

|

|

|

ManufacturingOur manufacturing facilities are at the heart of our site, and the constant all year-round operation. We have the latest machinery and skilled people to create, inspect and build our precision parts. Whether it be the buzz of the Machine Shop and grandeur of the operation, or the intricate detail and highly clinical environment to create a Composite part, each is crafted to the pinnacle of quality and precise specifications to maximise performance. |

|

|

|

|

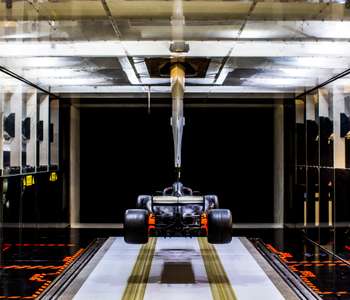

Wind TunnelA cutting-edge facility that’s as impressive as it is essential to our success. A 2.2MW motor drives carbon fibre blades which can generate a wind speed of up to 80m/s – a machine so powerful that it’s capable of going 30m/s faster than regulations will allow us to run it. This highly complex facility is paired with sophisticated measurement systems to allow us to meet our allocation of aerodynamic tests in a precise, efficient and cost-effective manner, giving us the insight we need to stay at the top of the sport. |

|

|

|

|

Design OfficeThis is the place where all approved ideas are turned into reality. Using the latest CAE and CAD technologies and tools our engineers simulate, develop and design all parts required to build and operate our race cars. Our team of highly skilled and driven engineers permanently strives to improve the performance and reliability of every single car part. |

|

|

|

|

Race SupportRacing is what it’s all about. But the magic doesn’t just happen trackside. Our factory-based engineers analyse telemetry data and video feeds in real time in a dedicated, high-tech facility at our Brackley site. Their in-depth analysis is used to provide feedback to the race engineers at the track using live intercom, allowing them to maximise the car’s performance. |