EES engineers conduct stringent preventative maintenance on all types of excitation equipment from early analogue to the latest digital systems ranging in type, size and age.

Our services extend to systems that are no longer supported by the OEM.

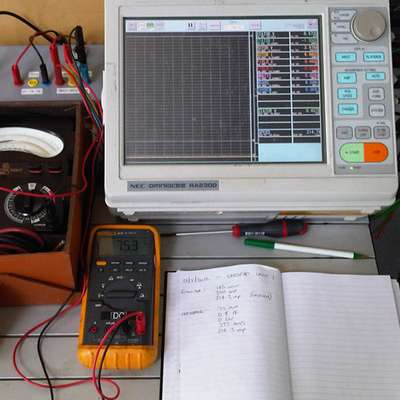

Typically maintenance will involve static testing that includes a visual inspection of the equipment, secondary injection and calibration check, relay testing, check of ancillary components and logic circuits.

Dynamic testing is used to complete the maintenance and verify the performance of the excitation system. This is typically performed with the generator on open circuit followed by online testing to assess excitation system performance including limiters and protective features.